Tie Guan Yin (also known as Ti Kuan Yin, Iron Buddha and Iron Godness of Mercy)is the most popular oolong tea in China and many parts of the world. It is produced in the Anxi County of Fujian Province.

Anxi has been producing tea for around thousand of years. It was noted that in end of Tang Dynasty, (around 950AD), an eminent monk surnamed Pei came from central provinces to the An Chang Temple on Si Ma Shan Mountain of Anxi. He made tea in the temple and also taught the Anxi farmers the tea processing. The farmers called the tea tree as Sheng Shu (Saint Tree) and the tea as Tian Sheng Cha (Saint Heaven Tea) for its great economic and health value after they learned the tea processing technology.

Hundreds of years later. a retired general Wu Long was hunting and plucking tea in the Mt. Nanyan Shan of Anxi, and accidentally he invented the Shake-Green technology. The Tian Sheng Cha he made by this technology is more fragrant and mellow sweet than previous traditional one. The farmers learned from him and updated their technology. The tea quality was even better then. In memory of the inventor of Shake-Green technology, the named the new tea by the name of the retired general Wu Long, (In English, Oolong). In Qing Dynasty, the imperial official Wang Shi Rang went back to his hometown Anxi for holiday, and he found theOolong Tea from the the farmers in Mt. Nanyan Shan. He brought back the newly found tea to the central palace. And later the tea was forwarded to the emperor Qian Long. The emperor liked the tea very much. He called in Wang Shi Rang to understand more details of this tea. After he know more about this tea, feeling the tea which is as heavy as iron in the hand and the tea body looks like the face of Guan Yin (Chinese Goodness of Mercy), He named the tea as Tie Guan Yin (Iron Godness). The time was 1741AD.

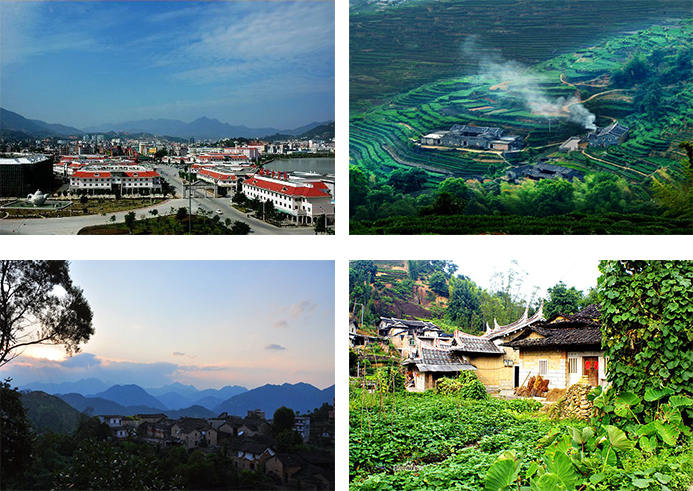

Anxi County is located in the south Fujian. The climate here is warm and often rains. And there are many mountains and streams in the region. The mountains are wet and cloudy on the top. The soil of Anxi County is mainly composed by yellow red earth. The geographic surroundings are very suitable for tea growing.

Most of the Anxi tea farmers make a living by tea. The Anxi tea farmers are diligent and smart. Besides the tea producing, many of them go out to many places of China to run tea business. Genrally whichever Chinese tea market you go, you will encounter tea shops run by Anxi people. The occupation in tea business promote the sales of Tie Guan Yin tea, and on the other hand enhanced the production development of Anxi Tie Guan Yin.

The classification of Anxi Tie Guan Yin

Anxi Tie Guan Yin is generally classified into two types.

Ⅰ Nongxiang- thick aroma

The thick aroma type is made by the traditional processing way, which is fermented (oxidized) deeper and more roasted. The Nongxiang Tie Guan Yin is characterized by browned dry leaves and brownish liquor, and the flavor is more ripe fruity or honey kind, the taste is stronger pure mellow. The processed tea leaf of Nongxiang Tie Guan Yin has the typical Oolong Tea characteristics, green leaf with red edge 绿叶红镶边, as that of Wuyi Rock Tea and Phoenix Dan Cong.

Ⅱ Qingxiang- light aroma

The light aroma type emerged in 1980s. It is made by updated modern processing. It is less fermented and roasted. The processing of light aroma type Tie Guan Yin is not so complicated and more mechanized than the thick aroma type. The character of light aroma Tie Guan Yin is closer to Green Tea than thick aroma one. The flavor of Qingxiang type is refreshing fragrant and the taste is moderate mellow. The dry tea has jade yellowish green color. And the tea liquor is greenish color. The brewed tea leaves also look green with much less red edge than the Nongxiang type.

In Chinese market, the Qingxiang type Tie Guan Yin is the dominant one. The overall young tea drinkers prefer the refreshing flavor and moderately strong taste of Qingxiang Tie Guan Yin. While the elder and experienced tea drinkers somehow is inclined to choose the Nongxiang type Tie Guan Yin for its heavy roasted ripe flavor and stronger taste. However in the market, good quality Nongxiang Tie Guan Yin is not easy to find, since the traditional processing of it is more complicated and involved in more skills and art work of the tea producers.

Tie Guan Yin is also the name of a tea cultivar of Anxi. In the market you will find a few other Oolong tea which look like Tie Guan Yin and also produced in Anxi and nearby area, with the names Huang Jin Gui, Ben Shan, Mao Xie and Jin Xuan. The later teas are made by cultivars Huang Dan, Ben Shan, Mao Xie and Jin Xuan respectively. These tea have some of their own characters in quality. While they are obscure to most of the tea drinkers.

Mu Zha Tie Guan Yin

Besides the Anxi Tie Guan Yin, There is also a Tie Guan Yin produced in Taiwan named as Mu Zha Tie Guan Yin. In 1896 the Taiwan Muzha Tea Company sent the brothers Zhang Nai Miao and Zhang Nai Gan to Anxi to learn tea processing. Besides the Tie Guan Yin tea processing technology, they also brought back the Tie Guan Yin tea cultivars to plant in Muzha region of Taiwan after they finished thier mission in Anxi. The Mu Zha Tie Guan Yin is actually the traditional Chinese Tie Guan Yin (as introduced before, Chinese traditional Tie Guan Yin is Nongxiang-thick aroma type.) The processing of Chinese traditional Nongxiang Tie Guan Yin is almost the same as the Mu Zha Tie Guan Yin.

The plucking standard of Tie Guan Yin

The plucking of Tie Guan Yin started in end of April when the tender tea leaves already grown up. The ideal plucking is the tender tea shoots with three leaves to five leaves will. As we know Oolong tea can not use too tender tea buds and too old tea leaves. In Summer the pluckign of Tie Kuan Yin will still go on. But the quality of Summer tea is considered as lower grade. It is astringent in taste. The Autumn crop of Tie Guan Yin is also good quality one. It is plucked in around middle of September lasting to middle of October.

The Processing of Tie Guan Yin is a bit different in between the traditional, Nongxiang type and the modern, Qingxiang type.

The following is the introduction of processing of the two types of Tie Guan Yin respectively.

Part Ⅰ Processing of traditional Tie Guan Yin.

The processing of traditional Tie Guan Yin is all conducted by hand. It is very hard working, and the more important it requires very high skills of the workers.

1 Sunlight withering After the fresh leaves was sent to the factory, they were put on the bamboo plate for sunlight withering. The ideal timing of sunlight withering is in the evening, and it lasts around one hour.

2 Indoor withering will come after the sunlight withering. During the indoor withering, the tea leaves will wither further. and also the indoor place will cool down the hot tea leaves after sunlight withering. The indoor withering will also last around one hour. In the end of the withering, the experienced tea worker will examine the condition of the tea leaves to decide if it is suitable to conduct next handling Zuoqing 做青, tossing.

3 做青 Tossing is the most critical processing to obtain the quality of Tie Guan Yin and also Oolong Tea. The tossing of Tie Guan Yin is conducted in a big bamboo pan and at night time. The bamboo pan is hanging on a string from the roof. And the worker will toss the big bamboo pan to produce upside down movement of the tea leaves. This movement will damage the cells on the edge and surface of the tea leaves. and the tea juice will come out from the damaged cells. After a round of tossing, the tea leaves will be left quiet for around 1-2 hours. During this time the extracted tea juice will produce fermentation (reaction under oxygen). Then another round of tossing will be conducted, and it will be followed with another round of leaving quiet. Generally The later rounds of tossing will be more violently conducted . And around five rounds of tossing will be conducted. It lasts overnight. When the tossing is finished, generally it is in the next morning. During the handling, the workers need use experience and insight to judge the timing and force of tossing to achieve best effect of the damage of tea leaves and fermentation. Tossing 做青 is the quintessence of Tie Guan Yin and Oolong Tea processing.

4 Frying is conducted to fix the quality formed in the tossing processing. Frying can be done in iron pan or iron drum. The most traditional processing adopt pan frying. The high temperature of frying will kill the enzymes in both the damaged tea cells and un-damaged tea cells. So part of a tea leaf (the edge and surface part )turn out to be the nature of black tea and other part of a tea leaf (the center and inner part) turn out to be the nature of green tea. This is the reason why Tie Guan Yin is Oolong Tea, partly fermented and partly un-fermented. The frying will last around ten minutes. And also the tea leaves will lose some water content in frying.

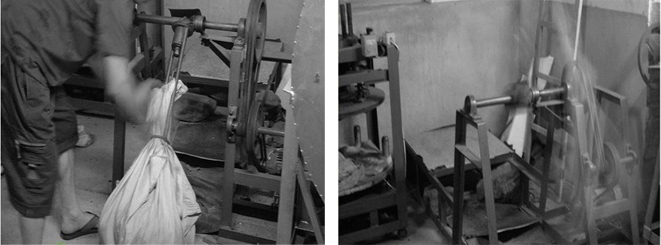

5 Rolling is conducted to make the tight tea body. and also the the juice will be squeezed out from the cells. The tea juice evenly stuck on the surface of the tea body will make it look shiny and oily. This is the traditional wooden rolling machine. (The modern Qingxiang type of Tie Guan Yin will not conduct rolling. It will be explained in the part of Qingxiang Tie Guan Yin processing).

6 First Baking. Baking is one of the other most critical processing to make the quality of traditional Nongxiang Tie Guan Yin. The tea is put on the surface of the bamboo basket. And charcoal is used to heat up the bamboo basket. During the baking, no any smoke is allowed to occur. The workers need to control the temperature and stir the tea to make sure the tea is baked evenly. The baking will stop after a certain loss of water content in the tea leaves, when the tea body is still soft.

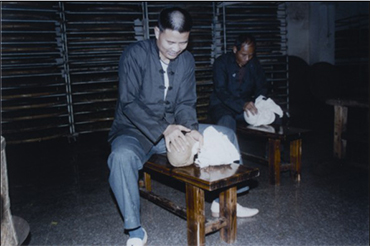

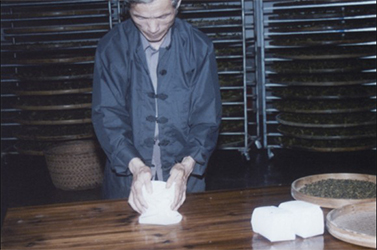

7 First Bag Rolling. Bag Rolling is conducted to shape the tightly round tea body of Tie Guan Yin. After the first baking, the tea is bagged in a cloth. Then it is rolled by hand. The bag will shrink during the rolling. So the tea body will be more and more tightly rounded. Bag Rolling is a kind of very hard hand working, it needs intensive force and lasts long time.

8 Second Baking will repeat almost the same handling as the First Baking. But the temperature in the Second Baking is a bit lower than the First Baking.

9 Second Bag Rolling is also the last time bag rolling.

After the second bag rolling, the tea body is finally shaped. Good quality traditional Tie Guan Yin tea body looks like the dragonfly head.

10 Third Baking is the last time baking. After the baking, the tea is dried enough. Generally the water content will control below 6%. And the tea color and shape of tea body is finally fixed.

11 Screening and Sorting. After the third baking, the main processing of Tie Guan Yin is finished. The whole processing last around 36 hours. Now it is necessary to conduct screening and sorting to sort out the stalk, dust and broken leaves to obtain the even quality of the finished tea.

12 Blending. The hand processing tea need blending to balance the quality from each shot of processing. The blending work need the experienced tea master or taster to do.

13 Packing. The traditional packing of Tie Guan Yin is packed in kraft paper. The Anxi people has the tradition of making the packing into a cuboid which looks like a pillow bag. And they just call the tea ‘pillow bag’. So do the Chaozhou people with the Phoenix Dan Cong tea. Anxi and Chaozhou is close in distance and culture. The storage of traditional Tie Guan Yin is easy. Generally to keep it away from moisture and odor in room temperature is OK. It can keep a few years. The vintage traditional Tie Guan Yin is cherished by many Chinese tea drinkers.

Ⅱ Processing of modern Qingxiang Tie Guan Yin.

1 Sunlight withering. the sunlight withering of Qingxiang Tie Guan Yin is a bit less intensively conducted as compared to the Nongxiang.

2 Indoor withering is also the necessary processing of Qingxiang Tie Guan Yin. Modern processing of Qingxiang Tie Guan Yin will install air-conditioner in the room to control temperature and humidity. During the indoor withering, the temperature of the tea leaves will cool down, and the water content will re-distribute evenly in the leaf structure.

3 做青 Zuo Qing, Tossing. As Oolong tea, tossing is one of the most critical processing to form the special quality of Qingxiang Tie Guan Yin. The after withering tea leaves are put in a big long round bamboo cage. and then the cage will be rotated by hand or motor. The rotation will produce colliding and damage of the tea leaves on the edge and surface. The rotation will last a few minutes. And then the tea leaves are taken out form the cage to put back in the bamboo plate. The worker will watch the condition of the tea leaves. If he feel the colliding of the tea leaves are not enough, he will shake the bamboo plate for some time to make sure enough tossing. This is a complementary handling to the rotation. Then the tea leaves will be kept quiet in the bamboo plate in the air-conditioned room for around one or two hours. During the keeping, the damaged part of the tea leaf will produce some fermentation (tea juice reaction under oxygen) and the water and some other ingredients in the tea leaf will re-distribute in the leaf structure. The master worker will keep watching the color change and smell give-off of the tea leaves to decide the start timing and intensity of next round of tossing.

The work requires experience and insight of the worker. After the keeping-quiet is enough, another round of tossing will be conducted. The tossing and keep-quiet will repeat for 3-5 rounds according to the actual condition of tea leaves and surroundings. It takes around 12 hours to finish the complete handlings.

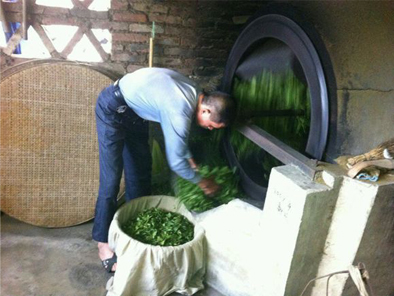

4 Frying is also translated as fixation. The tea leaves after tossing will undergo frying. The frying is generally conducted in the iron drum which is heated up to around 200℃ during operation. The high temperature will kill the enzymes in the tea leaves. So the reaction in the tea leaves stop and the quality formed in the tossing is fixed. The frying will also reduce some water content in the tea leaf.

5 Flinging. The biggest difference between the processing of Qingxiang Tie Guan Yin and traditional Nongxiang Tie Guan Yin is that after frying, the Qingxiang will conduct flinging processing, instead of the rolling processing of Nongxiang. The fried tea leaves are packed in a cloth bag, and then the bag will be kept flinging fiercely on the hard ground to break the leaf edge (fermented part) and too old leaves (these parts are more crispy after frying, so the flinging will break these parts.) After flinging, the leaves will undergo screening. So the broken pieces will be removed.

By flinging, most of the fermented part of the tea leaf will be removed. That’s why the Qingxiang Tie Guan Yin is closer to the nature of green tea, as compared to Nongxiang Tie Guan Yin. When we are brewing Tie Guan Yin, we can also find that the leaves of Qingxiang is more broken and the color is green, while the Nongxiang one is more complete, and the color is ‘green center with red edge’ 绿叶红镶边. The flinging can also be handled by a simple machine.

6 Bag Rolling. After flinging, The tea will be packed tightly in a cloth bag. And then the bag will be put inside a round rolling machine. The bag will be tightly rounded by the machine into a ball. So the tea in the bag is shaped. After some time, the rolling will stop. And the bag will open. The tea will undergo block dismissing.

After block dismissing, if the tea leaves are too soft, they will be baked for a while to lose some water.

Then the tea will be tightly packed in the cloth bag again for next round of bag rolling. The bag rolling will repeat for more than thirty times to achieve the ideal body shape of Tie Guan Yin. During the processing, the worker will judge if the leaves are too soft to shape. If indeed, they will be baked for some time to lose some more water. In the end, when the ideal tightly round shape of Tie Guan Yin tea body is achieved, the bag rolling processing will stop.

7 Baking. After bag rolling, the body shape of the Tie Guan Yin is made. Baking will finally dry and fix the shape of tea body. Generally the baking of Qingxiang Tie Guan Yin is done in electric oven. The temperature of the oven is controlled at around 60℃ and it will last around six hours till the tea is finally dried. The water content will be below 6%.

8 Sorting. After the tea is finally dried, the maocha Tie Guan Yin is made. it will further undergo sorting to remove the stalk and dust. Then it is the Tie Guan Yin product.

Changsha Wufeng Tea Co.,Ltd ® Copyright Reserved

Tags: Tie Guan Yin

Category: Uncategorized